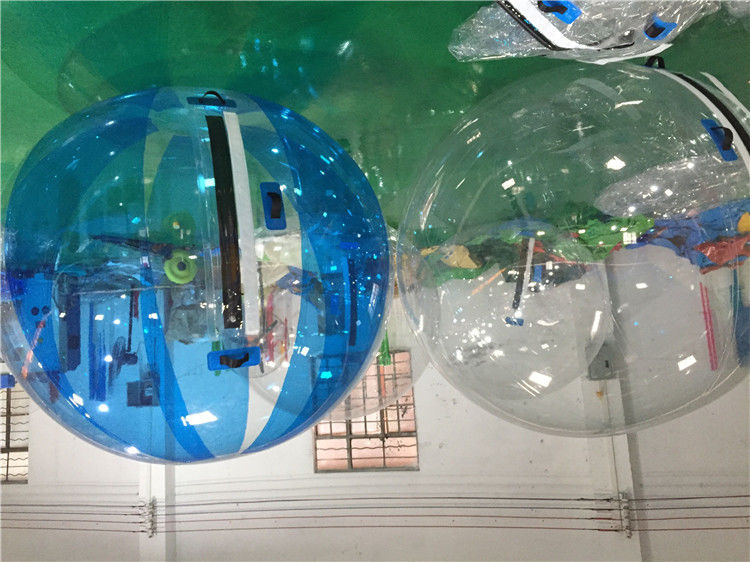

PVC / TPU Outdoor Inflatable Toys White 2m Walk On Water Balls , Children Inflatable Water Walking Ball

Product Details:

| Place of Origin: | China |

| Brand Name: | Barry |

| Certification: | CE, EN14960, , SCT, EN71 |

| Model Number: | HBY-Toys-010 |

| Document: | Product Brochure PDF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Piece |

|---|---|

| Price: | USD1-220/Piece |

| Packaging Details: | Product is packed by strong PVC bag and carton for blower, pump and other accessories |

| Delivery Time: | 7-10 Working Days |

| Payment Terms: | T/T, Paypal, Western Union |

| Supply Ability: | 500 Pices/Month |

|

Detail Information |

|||

| Size: | Dia1.2m, Dia1.5m... | Material: | PVC/ TPU |

|---|---|---|---|

| Accessory: | CE/UL Blower And Repair Material | Printing: | Available |

| Payment: | T/T, Paypal, Western Union | Technique: | Welded |

| Life Span: | More Than 3 Years | Color: | Blue |

| Highlight: | inflatable yard toys,inflatable kids toys |

||

Product Description

Outdoor Inflatable Toys white 2m walk on water balls,children playing ball on water

Specification

1. Product development and design

We use Rhino, CAD, CDR, Al to complete our design. Accurate to every detail (pulling ring, handle).

2.CNC cutting

High-precision CNC cutting, the data is more intuitive, more accurate, and the error is small.

3. Manual measurement

For places where machine cutting is not possible, manual measurement and cutting are used. High flexibility and easy calculation.

4.High frequency welding

Our company has mature high-frequency welding technology, and high-frequency current connects the products together. Although high-frequency welding is mostly used for metal welding, when used for PVC welding, the welded product is strong and reliable, and has strong tear resistance.

5. Hot air welding

Hot air welding is one of the main welding processes for product manufacturing. The electrodes are heated with preheated compressed air and welded together.

6. stitch

Needle sewing, here we use double-sided sewing procedure. Both beautiful and solid.

7. Product testing

Each product is fully tested (48 hours) before packaging.

8. Compressed air

After testing the product without defects, drain the air and compress the bundle.

9. Clean packaging

Final packaging in clean room.